Millgrain Machinery Industries

High Performance Technologies

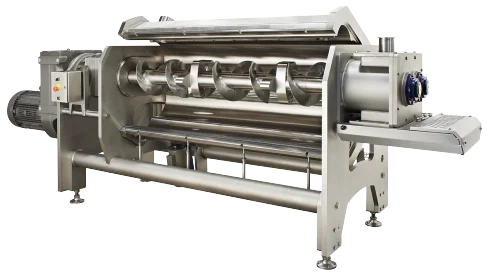

Mg Automatic Blending Machine

Description

- The mixing process to achieve it is often called homogenization. Thorough blending and homogenization are desirable when manufacturing food products precisely because these processes ensure consistency. Ribbon Mixer is an ideal mixing quality for moist, dry, and viscous materials at variable filling levels and they are convective mixers. Ribbon blenders are actually used in many industries and applications: pharmaceuticals, food and bakery, cosmetics, plastics, spices, mixes for drinks, cements grouts and mortars, coffee and tea, tobacco. The moderate shear of the ribbon or paddle naturally breaks down lumps and agglomerates. The inner and outer ribbons together rotate the mass of material. The outer ribbon moves the solids toward the centre of the tough and the inner ribbon moves solids toward the ends. Mixing time for a fully loaded mixer is typically 15 minutes and is proportional faster for lower loading

- Here the mixture movement is forced by the rotation of the ribbon which is circulating the product in 2 directions: the ribbon is actually made in 2 parts; 1 external ribbon circulates the product in 1 direction while another ribbon located inside the 1st one moves the product in the other direction. By mixing enough time, those 2-axial movement, coupled with some radial movement (blades “cutting” the material when rotating), will allow to reach the required degree of homogeneity

- Millgrain offers AutomaticRibbon Mixer Cum Blender is a continuous mixer can produce a wide variety of baked goods ranging from crackers and bagels to soft bread and buns. It is a high shear mixer used for solid / solid mixing, solid/ liquid mixing, for all dry foods products, nutraceuticals, protein powder mixes, dry juice mixes, chemicals, fertilizer, insecticides, colorants, resins and polymers. Ribbon Mixer Cum Blender can be provided according to customer enquiry

Application

- Especially for baked goods mixing

- Used in food and ingredients infant formula, cocoa mix, instant salad dressing, cake mixes, spices, seasonings, flavourings, gelatine

- Used in process industries for bulk solids dry Mixing

- Very simple and robust solution to mix dry materials

- Single shaft paddle design may be advantageous for very poorly flowing materials, fragile materials or if the batch size may be as low as 15-20% of the nominal batch size

Advantages

- Compact structure

- Speed adjustable

- Homogeneity is maintained

- Heavy-duty drive unit

- Better design

- Low energy consumption

- Stainless Steel construction

- Small area coverage

- Resistant to wear

- Heating/Cooling Jacket for ribbon blender

- Spraying Nozzle for liquid

- Long service life

- Good discharging rate of the mixer